Have you ever seen such a technology that can reach those distances that human eyes can only imagine? Light Detection and Ranging or Lidar is such a technology. Using rapid-fire laser emissions, this cutting-edge technology provides an exact 3D representation of distant objects in the surrounding environment. Lidar laser is revolutionizing various industries and therefore gaining popularity among people.

However, due to the complexity of this technology, it is difficult for everyone to understand it. That’s why you may have common doubts regarding LiDAR. So with this blog, we have brought detailed answers to some frequently asked questions on lidar lasers to make you more understanding of this technology.

LiDAR is an advanced remote sensing technology that uses lasers to measure distances and create 3D maps of surrounding areas. Lidar lasers are mainly of two types, topographic lidar and bathymetric lidar. Topographic lidar performs 3D mapping of landscapes using near-infrared lasers. On the other hand, the bathymetric lidar incredibly constructs the 3D map of seafloor and riverbeds using water-penetrating green light.

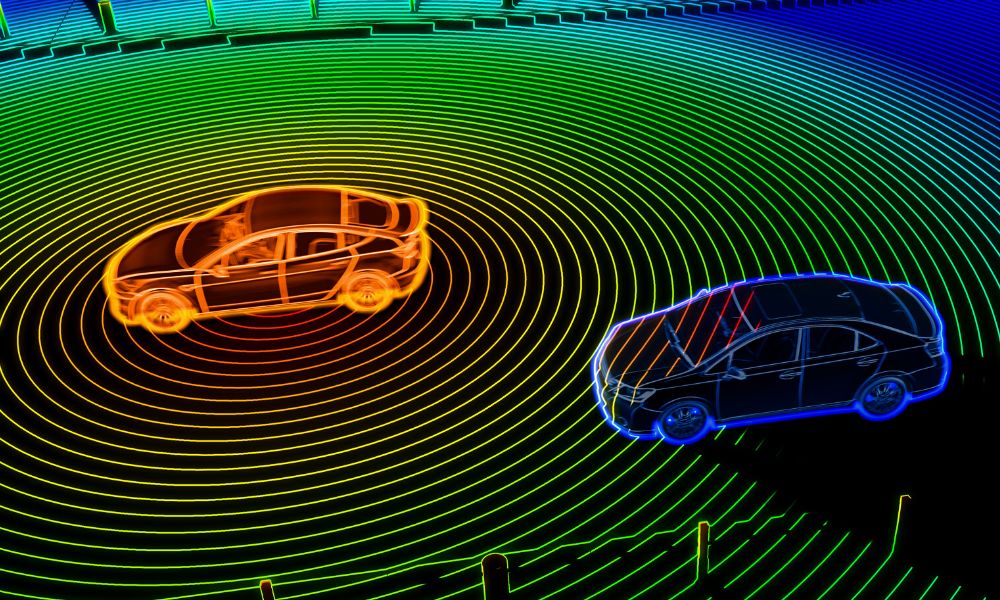

Lidar’s system is made up of several key components. It consists of a laser source emitting light pulses, a scanner that sends laser beams in different directions, and a receiver that detects the reflected light beams. The data collected by lidar is then processed to create detailed three-dimensional maps, often referred to as point clouds, which represent the physical characteristics and spatial layout of the scanned area.

The technology’s applications are far-reaching and diverse. Lidar has become essential in the realm of autonomous vehicles, providing crucial data for navigation and obstacle detection. It is extensively used in mapping, surveying, environmental monitoring, industrial inspections, and even archaeology.

Lidar laser technology is renowned for its high level of accuracy in distance measuring and 3D mapping. Lidar is typically used to map a few centimeters to a thousand miles successfully. However, the accuracy of the lidar can vary depending on some important factors like configuration, the specific technology, and the application area.

The divergence of the laser and the calibration and alignment of the system affect its accuracy in many ways. In terms of distance measurements, lidar can typically achieve sub-centimeter or millimeter-level accuracy for short to medium ranges. This level of precision is particularly crucial in applications like autonomous driving, where accurately detecting and localizing objects is essential for safe navigation.

On the other hand, if we talk about 3D mapping, its accuracy depends on the density of the applications. High-density clouds and finer resolution systems help in creating optimum and accurate 3D structures. It’s also important to note that lidar accuracy can also be affected by external factors such as atmospheric conditions, target reflectivity, and surface characteristics. For example, adverse weather conditions or highly reflective surfaces can introduce some level of measurement uncertainty.

This technology is generally considered safe but only when it is used within regulatory guidelines. The laser used in the lidar technology to measure distance is low-powered and eye safe. This means it does not cause any potential harm to the human eye. During manufacturing, manufacturers take special care according to the standard protocols.

Lidar technology is subject to regulations and safety standards imposed by various regulatory bodies, such as the International Electrotechnical Commission (IEC). These regulations aim to ensure that lidar systems meet specific safety requirements and operate within acceptable power levels and exposure limits.

The sensor of the lidar laser is designed to allow individuals to operate it from a safe distance. During use, its laser pulses gradually dissipate as well as become weak so that the safety measures remain intact. Operators and manufacturers must follow guidelines to maintain safe distances and minimize potential hazards.

The process of manufacturing a Lidar laser typically involves several steps. First, a laser diode is selected based on the desired wavelength and power output. At Inphenix, our skilled engineers and researchers first understand the needs of the customers according to their demands for specific applications.

Understanding the application, a tailored blueprint is prepared with the assembly of major components. We always prioritize high-performance components that meet stringent quality standards and desired specifications.

After this, we utilize advanced semiconductor fabrication techniques to create laser diodes, including epitaxial growth, lithography, etching, and deposition processes. Precision machining and assembly techniques are employed for other optical components. After fabrication, optical alignment and adjustments are done while assembling all the critical parts.

We perform calibration procedures to fine-tune the lidar laser system, ensuring optimal performance and accuracy during quality control checks. Once the lidar lasers pass all quality control tests and calibration procedures, we carefully package and prepare them for shipment to customers.

Lidar laser is a revolutionary technology that can be proven as a game changer in the future for various industries. It has the capability to reach us to those distances which we can only imagine. But the right use of this technology is very important. That’s why all the confusion related to the lidar laser should be cleared before use. Through this blog, we have cleared some common doubts. But if you have any other questions related to Lidar Laser, then you can feel free to reach us.